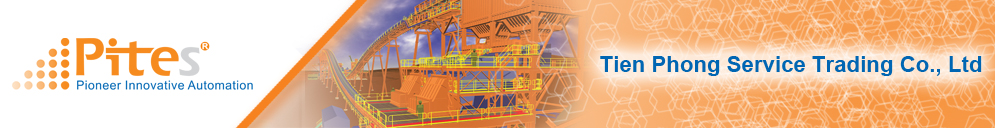

Thiết bị kiểm tra đường ghép mí lon SeamSight-B

Xuất sứ: Hongkong

Nhà cung cấp: PITES

Hãng sản xuất: canneed

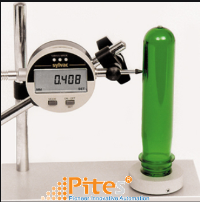

Thiết bị kiểm tra đường ghép mí lon (Seam monitor)

Model SeamSight – B

Hãng sản xuất: CANNEED

Dùng cho lon nước giải khát (for beverage cans)

-Phương pháp: các mối ghép được đo bằng camera và được số hóa bằng máy vi tính.

-Máy sử dụng phần mềm hiển thị được hình ảnh mối ghép. Hình ảnh có thể in bằng máy in hoặc lưu trữ trên máy vi tính.

-Xuất kết quả đo sang Excell.

-Cổng giao tiếp: RS232

-Độ phân giải 0.001 mm

-Độ chính xác: ±0.005 mm

-Thời gian đo nhanh.

-Nguồn điện: 230V/ 50Hz

Cung cấp bao gồm:

+Máy chính Model SeamSight – B: full automatic seam monitor (for beverage cans)

+Phần mềm Seam Sight 4.0: professional seam

measuring software software

+Mẫu chuẩn VSM-CAL2 Calibration piece 2mm

+Tài liệu hướng dẫn sử dụng

SeamSight®-B

Full Automatic Seam Monitor

Most hot-selling around the world for 4 consecutive years, leading technology, auto measuring and data collection, interference-free of external light source

CanNeed and Seam Sight are the registered trademarks of CanNeed Instrument Ltd.

CanNeed and Seam Sight are the registered trademarks of CanNeed Instrument Ltd.

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second! The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management. The result statistic and result chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

The CanNeed Seam Sight® Full Automatic Seam Monitor has adopted the advanced optical system and Golden Lens® video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam Sight® system is equipped with the new seam measuring software Seam Sight®.

SeamSight®-B Full Automatic Seam System

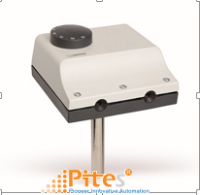

The CanNeed Seam Sight ® -B system can automatically collect the data from STG-200-d Seam Thickness Gauge and CSG-d Countersink Gauge. The actual seam hickness and countersink can be generated reports together with other data. To optimize the measurement process.

Measurement Process

Before cutting the sample can, use STG-200-d Seam Thickness Gauge to measure the seam thickness rate; meanwhile, use CSG-d Countersink Gauge to measure the countersink rate; then the Seam Sight -A will collect the both data automatically.

After that, the sample can should be cut with CSS-1000 Anti-noise Seam Saw or CSS-2000 Seam Saw and placed at the camera position of the monitor. Then, the seaming images will be displayed on the screen. The auto measurement will be finished within 1 second if you press the “Confirmation” button. All images and measurement data will be saved in the system data base.

Seam Sight® system collects the data of STG -200-d Seam Thickness Gauge (digital) and CSG-d Countersink Gauge automatically. And transfer the data to computer by a cable. Generate reports with the actual seam thickness, actual countersink and other datas. The measurement process is optimized.

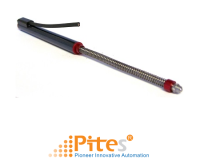

As the seam thickness measured by Seam Monitor is not accurate after cutting, the STG -200-d Seam Thickness Gauge (digital) can measure the actual seam thickness