THICKNESS CHECK CALIX- KIỂM TRA ĐỘ DÀY CALIX

Xuất sứ: Germany

Nhà cung cấp: PITESCO Việt Nam

Hãng sản xuất: lap-laser

THICKNESS CHECK CALIX

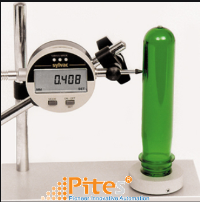

CALIX - Our solution for non-contact thickness measurement of flat products

YOUR GUARANTEE OF QUALITY FOR THE THICKNESS MEASUREMENT OF SHEET METAL AND STRIP STEEL

For the manufacturing of a perfect cold strip, many factors are crucial. Our measuring frames specifically check the thickness-related quality parameters of the strip steel or steel sheet. Free of radioactive radiation, laser sensors are used in the cold strip areas that do not require protection measures with laser class 2, or only low precautions when using laser class 3B sensors.

For the manufacturing of a perfect cold strip, many factors are crucial. Our measuring frames specifically check the thickness-related quality parameters of the strip steel or steel sheet. Free of radioactive radiation, laser sensors are used in the cold strip areas that do not require protection measures with laser class 2, or only low precautions when using laser class 3B sensors.

The installation of our measurement systems is quick and uncomplicated for our customers. The CALIX is integrated into the line with its C-shaped frame across the material flow. Our solutions with and without traversing determine all important parameters for quality assurance, including strip thickness, edge thickness, wedge or cambering, and measure the complete thickness profile. Thus, you have full process control in the current production.

FEATURES OF THE CALIX

EASY TO USE

The measuring system is able to perform a calibration during production to ensure the desired measurement result.

HIGH ACCURACY

LAP's CALIX achieves leading accuracy in the market at comparable measuring ranges.

TEMPERATURE INDEPENDENT

The LAP measuring system can be used in harsh environments with material temperatures up to 200 ° C.

2 VERSIONS

CALIX S

The compact measuring frame of the LAP CALIX S is especially suitable for edge measurements on the production line and for small strips. Due to its space-saving design as well as fast calibration, the LAP CALIX S is an ideal complement to all cold strip processing lines.

CALIX XL

For measurements in the centerline of the material or over the entire material width, the LAP CALIX XL offers the right solution with its traversing thickness measurement.

THE CALIX SOFTWARE

The laser sensor transmits up to 4000 measured values per second to the software. You will receive a detailed evaluation with all measured minimum, maximum and average values. In addition, the standard deviation as well as the Cp and Cpk values are calculated.

FEATURES OF THE CALIX

EASY TO USE

The measuring system is able to perform a calibration during production to ensure the desired measurement result.

HIGH ACCURACY

LAP's CALIX achieves leading accuracy in the market at comparable measuring ranges.

TEMPERATURE INDEPENDENT

The LAP measuring system can be used in harsh environments with material temperatures up to 200 ° C.

2 VERSIONS

CALIX S

The compact measuring frame of the LAP CALIX S is especially suitable for edge measurements on the production line and for small strips. Due to its space-saving design as well as fast calibration, the LAP CALIX S is an ideal complement to all cold strip processing lines.

CALIX XL

For measurements in the centerline of the material or over the entire material width, the LAP CALIX XL offers the right solution with its traversing thickness measurement.

THE CALIX SOFTWARE

The laser sensor transmits up to 4000 measured values per second to the software. You will receive a detailed evaluation with all measured minimum, maximum and average values. In addition, the standard deviation as well as the Cp and Cpk values are calculated.

TECHNICAL DATA

| Calix S 10 | Calix S 30 | CALIX XL 30 | |

| Measuring range | 10 mm | 30 mm | 30 mm |

| Measuring depth | 250 mm | 250 mm | 1,070 mm |

| Throat depth | 300 mm | 300 mm | 1,300 mm |

| Throat height | 200 mm | 200 mm | 200 mm |

| Resolution | 0.2 mm | 0.5 mm | 0.5 mm |

| Repeatability | ±0.35 μm | ±1 μm | ±0.5 μm |

| Accuracy | ±2.5 μm | ±7.5 μm | ±2 μm |

| Dimensions [H × W × T] | 623 × 164 × 511 | 623 × 164 × 511 | 800 × 300 × 1,645 |

| Weight | 20 kg | 20 kg | 230 kg |

| Laser type, wavelength, colour | Diode, 670 nm, red | Diode, 670 nm, red | Diode, 670 nm, red |

| Laser class | 2 / 3B | 2 / 3B | 2 / 3B |

| Protection class | IP 65 | IP 65 | IP 65 |