STRAIGHTNESS CHECK X-LINE

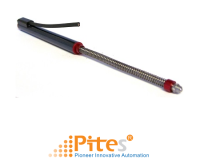

LAP's laser gauge for straightness measurement of bars and tubes

KEY FIGURES

KEY FIGURES

0.1mm per meter accuracy

140mm max. material diameter

8mmax. material length

800Hzmeasuring rate

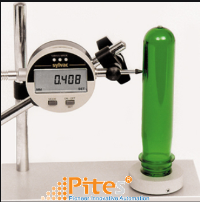

PRECISE STRAIGHTNESS MEASUREMENT OF ROUND WORKPIECES

With our innovative laser technology, you can check the straightness of a round profile inline and with a single measuring routine. The measuring frame with will be installed directly in your existing line and contains at least three pairs of measuring sensors. The object rolls through the measurement system in the inspection process and is scanned. The measurement result shows the deviation of the straightness in mm related to a reference length of one meter. Optionally, you can determine additional parameters such as length and ovality of the object.

With our innovative laser technology, you can check the straightness of a round profile inline and with a single measuring routine. The measuring frame with will be installed directly in your existing line and contains at least three pairs of measuring sensors. The object rolls through the measurement system in the inspection process and is scanned. The measurement result shows the deviation of the straightness in mm related to a reference length of one meter. Optionally, you can determine additional parameters such as length and ovality of the object.

Together for your success

This process is unique on the market and was developed with our partner sema Systemtechnik. You receive a verifiable quality assurance of your rods or pipes in the current production. The modular design allows individual configurability and can be easily integrated into the existing system. Benefit from the competence and experience of two strong partners.

FEATURES OF THE STRAIGHTNESS CHECK X-LINE

FLEXIBLE PRODUCT SIZES

The controlled material guidance during the entire production process allows rods and tubes of different sizes and lengths to be tested without difficulty.

NON-CONTACT MEASUREMENT

With our optical method, you can detect the straightness non-destructively and avoid any mechanical wear on the measuring system or the product.

MATERIAL INDEPENDENT

The Straightness Check X-Line measures independently of physical or chemical material properties, color or reflectance. The measuring system can thus be used flexibly.

FEATURES OF THE STRAIGHTNESS CHECK X-LINE

FLEXIBLE PRODUCT SIZES

The controlled material guidance during the entire production process allows rods and tubes of different sizes and lengths to be tested without difficulty.

NON-CONTACT MEASUREMENT

With our optical method, you can detect the straightness non-destructively and avoid any mechanical wear on the measuring system or the product.

MATERIAL INDEPENDENT

The Straightness Check X-Line measures independently of physical or chemical material properties, color or reflectance. The measuring system can thus be used flexibly.

X-LINE SOFTWARE

The intuitive software reads the measured values and calculates the straightness and the diameter during the process. The measurement results are evaluated based on the product specifications and tolerance violations signaled via digital outputs.

The intuitive software reads the measured values and calculates the straightness and the diameter during the process. The measurement results are evaluated based on the product specifications and tolerance violations signaled via digital outputs.

TECHNICAL DATA

Profile type round

Measurement of straightness; diameter and ovality are optional

Material flow through measurement range crosswise to orientation of long product

Material length up to 8,000 mm* *larger material length upon request

Number of sensors 3-16

Distance between sensors 0.5 m* *other sensor distances upon request

Measurement frequency 800 Hz

Laser class 2

Material temperature 0 - 100°C

Ambient temperature 0 - 45°C

Operating voltage 24 V DC ± 20 %

Interfaces of measurement system Level 2; iba* *other interfaces upon request

Blower unit included

Humidity of intake air 35-85 % humidity, not condensing

Profile type round

Measurement of straightness; diameter and ovality are optional

Material flow through measurement range crosswise to orientation of long product

Material length up to 8,000 mm* *larger material length upon request

Number of sensors 3-16

Distance between sensors 0.5 m* *other sensor distances upon request

Measurement frequency 800 Hz

Laser class 2

Material temperature 0 - 100°C

Ambient temperature 0 - 45°C

Operating voltage 24 V DC ± 20 %

Interfaces of measurement system Level 2; iba* *other interfaces upon request

Blower unit included

Humidity of intake air 35-85 % humidity, not condensing